What is a Lightweight Steel-Frame House?

The manufacturing of lightweight steel-frame house structures is a rapidly growing sector in the construction industry, offering fast, cost-effective, and sustainable solutions. These buildings' structural systems are typically made of steel or wood, but steel-frame technology stands out due to its durability and versatility.

What is a Lightweight Steel-Frame House?

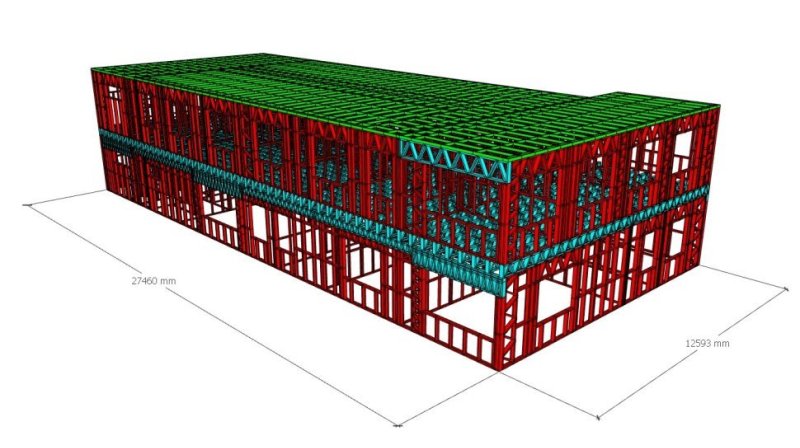

Lightweight steel-frame houses are buildings constructed from prefabricated, modular elements. These elements are manufactured in a factory and can be quickly assembled on-site. The structure is typically composed of galvanized steel profiles or wooden elements, combined with various cladding and insulation materials.

Advantages of Steel-Frame Lightweight Houses

1.) Fast Construction

- The manufacturing and assembly of steel-frame elements are significantly faster than traditional construction methods.

- Since the elements are prefabricated, on-site work is minimized.

2.) Lightweight and Durable Structure

- Steel is a lightweight yet extremely strong material, ensuring the stability and longevity of the building.

- It is resistant to environmental factors such as insects, fungi, and moisture.

3.) Excellent Earthquake Resistance

- The flexibility of steel structures allows them to withstand seismic movements better, making them ideal for earthquake-prone areas.

4.) Cost-Effectiveness

- Using prefabricated elements reduces construction time and labor costs.

- Steel-frame structures require low maintenance, leading to long-term savings.

5.) Sustainability

- Steel is recyclable, making lightweight steel-frame houses an environmentally friendly solution.

- Minimizing construction waste and creating energy-efficient structures contribute to sustainability.

Manufacturing Process

1.) Design and Engineering Preparation

- Creating architectural plans and conducting structural calculations.

2.) Prefabrication

- Manufacturing structural elements such as steel profiles and panels in a factory.

- Integrating insulation and coatings during production.

3.) Transportation

- Delivering the prefabricated elements to the construction site.

4.) On-Site Assembly

- Assembling elements on-site, including walls, roof structures, and other components.

5.) Finishing Work

- After structural completion, installing mechanical, electrical systems, and interior finishes.